Call us today on +44 (0)1493 659 411

CALL NOW FOR A FREE QUOTE

Lifeboat Capsule Systems

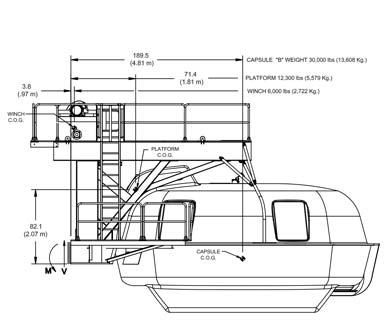

At SSI we specialise in the design, manufacture and world-wide delivery of lifeboat capsule systems. From 21 capacity to 80 capacity, we cover all sizes, budgets and needs.

Since building the first lifeboat specifically designed for offshore evacuation in 1968, SSI’s single cable capsule has been used in over 60 emergency evacuations and safely evacuated more than 2000 offshore workers.

Our Lifeboats

As the original designers of the Single Fall Lifeboat Capsule, Survival Systems International have been specialising in manufacturing lifeboat capsules and lifeboat related products for decades.

Lifeboat Capsule Benefits

With their specifically designed safety features, stable hook design and safer recovery from water, not only are SSI’s lifeboat capsules safer in emergency evacuations but are safer in training and maintenance.

Specifically Designed for Rigs & Platforms

The SSI Capsule is the only lifeboat designed specifically for the offshore oil worker’s use and safety; it is not an adapted ship’s lifeboat that has been designed for seamen. Single cable capsules do not go on ships, they are specifically designed for, and used by, offshore rigs, platforms and FPSO's.

Single Cable Advantages

SSI's capsules utilise a single cable for raising and lowering due to the significant safety advantages that it offers. The fundamental function of raising and lowering a weight is easier, more logical and safer using a single point and single cable.

Superior Hook Design

SSI’s hook is a stable design where the weight of the boat holds the hook closed when under load.

What does this mean? When the lifeboat is in the air, the SSI hook inherently wants to stay closed unlike other hook designs that want to open. This makes the SSI hook a much safer solution.

NEED TECHNICAL SUPPORT?

Get in touch today to discuss your project and receive a technical brochure.

Superior Structural Strength

The capsule has superior structural strength with its central core design, oval shape and use of fire retardant vinyl ester resin throughout.

Superior Maneuverability

The capsule’s oval shape allows for superior maneuverability in the water plus its beam to length ratio provides enhanced stability in rough seas.

Safer Recovery

A single point connection combined with enhanced helmsman visibility and superior manoeuvrability make the SSI capsule faster, safer and simpler to recover.

Why work with SSI?

With over 50 year experience in the lifeboat safety industry, your company,

crew and lifeboats are in the safest hands.

50+ Years Experience

SSI have the safest lifeboat track record in the life saving industry with over 50 years’ experience of focusing 100% on servicing lifeboats.

Worldwide Services

SSI can manage your entire lifeboat fleet offering a full range of lifeboat services worldwide from inspections and repairs to training.

Lower Costs

SSI lifeboats offer the longest lifespan of any lifeboat with significantly reduced maintenance needs and lower operational costs.

Patented Hook Design

All SSI lifeboats work with our patented hook technology.

Our Triple5LX hook is the safest hook in the industry.

ISO Compliant

At SSI we pride ourselves on being the frontrunner in the development of international ISO safety standards for lifeboat servicing and training.

More Information: PDF Downloads

For full technical information, please see our PDF downloads below:

Do you have lifeboat Concerns?

ssi are here to HELP

Q. Are your Operational costs too high?

Q. Concerns over Lifeboat compliance?

Q. At risk of down manning or vessel detention?

Q. Are your hooks safe and compliant?

If you are answering

YES

to these questions.

Enquiry Form

Please fill in the enquiry form below and we will reply with 48 hours.

To ensure a swift and accurate reply,

please add all pertinent information to your query, thank you.